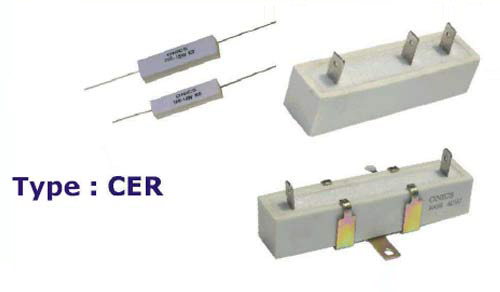

Ceramic Encased Wire Wound Resistor

Description

Technological excellence, sophisticated manufacturing process & expert technocrats enable us to manufacture premium quality resistors. All our resistors are quality certified and exhibit optimum performance.

A ceramic encased wire wound resistor is a robust and reliable passive electronic component used to control current flow in circuits. This type of resistor is constructed by winding a resistive wire, typically made of an alloy like nichrome, around a ceramic core. The ceramic casing provides excellent thermal and mechanical protection, ensuring stable performance under varying environmental conditions. These resistors offer high power handling capabilities and low temperature coefficients, making them ideal for industrial and high-power applications. With their precision and long-term stability, ceramic encased wire wound resistors play a vital role in electronic devices, amplifiers, power supplies, and motor control systems.

Construction:

These resistors are made by winding resistive wire on fibre glass cord or ceramic rods.Terminals are crimped or welded to end caps. This resistors assembly is then encapsulated in ceramic boat with high Temperature and fire retardant cement

ERPL is a ceramic encased wire wound resistor manufacturer based in New delhi ,INDIA supplying ceramic resistors to customers all over the world.

Our other types of wire wound resistors include:

- Coiled wire resistors (OCR)

- Double coiled resistor (DCR)

- Silicon coated resistor (SVR)

| Ohmic Range | 0.01W - 50K |

|---|---|

| Tolerance | ± 10% Lower Tol. available |

| Power Ratings | 2-40 Watts |

| Temp. Co-eff. | 50 PPM/100 PPM/ 260 PPM |

| Dielectric Voltage | 2500 V |

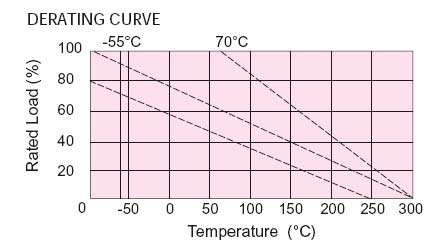

| Operating Temp | 250°C Max |

- Economical Fire-Proof Case

- Completely Welded Construction

- High Resistance Values Available.

- Non-Inductive type Available.

These Resistors are applied where high wattage dissipation is required in a small space. The metal heat sink ensures good heat dispersal & allows a low hot-spot temperature. Major appliactions include Induction furnace, Medical equipments, Humidity Chambers etc.

| Watts@ 20°c with heatsink | DIMENSIONS (MM) | Approx. Weight(g) | |||

|---|---|---|---|---|---|

| L1 | L2 | W | H | ||

| 2W | 18 | 7 | 0.8 | 35 | 1W-2k |

| 3W | 22 | 8 | 0.8 | 35 | 1W-3k |

| 5W | 22 | 10 | 0.8 | 35 | 0.01W-10K |

| 7W | 35 | 10 | 0.8 | 35 | 0.01W-20K |

| 10W | 48 | 10 | 0.8 | 35 | 0.01W-30K |

| 15W | 60 | 12 | 0.8 | 35 | 0.01W-40K |

| 20W | 60 | 14 | 0.8 | 35 | 0.1W-50K |

| 30W | 76 | 19 | Clip-Terminals | - | 0.01W-60K |

| 40W | 90 | 19 | Clip-Terminals | - | 0.1W-70K |