High-power punched Grid Resistors, or HPGRs, are very important parts of heavy-duty electrical systems. Because these resistors are made to handle more power, they are very useful in many industry settings. High-power punched Grid Resistors are different from regular resistors because they are designed to get rid of a lot of heat while still being stable and reliable. This blog will discuss HPGGRs, their use, and the methods that make them important to power resistors.

The Significance of High-Power Resistors

It’s impossible to say enough good things about high-power resistors. They are very important when a lot of electricity needs to be controlled. In electric cars, for example, high power resistors are used in regenerative stopping systems to eliminate extra energy safely. They are important in power sources, testing tools, and energy distribution devices. HPGGRs are the best choice for engineers and designers who want speed and dependability because they can handle high temperatures and offer precise resistance levels.

Key Applications of Power Resistor Technologies

A wide range of businesses use high-power resistors in many different ways. The need for effective power resistor applications keeps growing in fields like telephones and cars. In industrial automation, HPGGRs control motors well in drive systems. In the field of green energy, they are necessary for solar converters to convert energy properly. Because they can do so many things, HPGGRs are important for both current technologies and new ones that will come out. This helps businesses reach their energy and performance goals.

Innovative Resistor Manufacturing Techniques

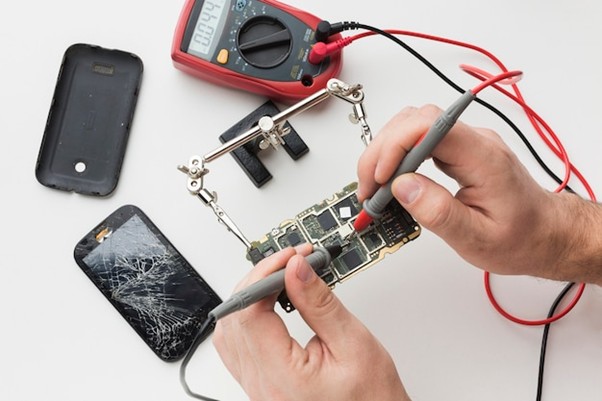

Advanced methods are needed to make high-power punched grid resistors that work well and last long. Resistor manufacturing techniques like laser cutting and precise punching make it possible to make complex shapes that improve performance and heat escape. Materials like metal alloys and ceramics are also picked based on how well they conduct heat and fight it. Custom resistor designs that meet the needs of a specific application can be made using these manufacturing methods. This gives engineers the freedom to make systems that meet their needs.

Custom Resistor Designs for Unique Applications

One great thing about high-power resistors is that they can be changed to fit your needs. Custom resistor designs let engineers choose the resistance levels, sizes, and important thermal properties they need for their projects. This skill is especially useful in niche areas where standard parts might not work. Companies can work with makers to make customized solutions that meet and beat performance standards, making their systems more efficient overall.

The Role of HPGGRs in Electrical Safety

In electrical engineering, safety is very important, and high-power resistors are a key part of ensuring process safety. HPGGRs are made to deal with extra energy and keep things from getting too hot, which could cause circuit failures or even fires. Their strong construction helps lower these risks, which is why they are necessary in dangerous places like power plants and factories. By using effective high-power resistors in their designs, engineers can make systems that are safer for both people and equipment.

Conclusion

In heavy-duty circuits, you can’t do without high-power punched grid resistors. They are very important in many situations because they can safely and effectively handle large amounts of energy. The future of high-power resistors looks bright because resistor manufacturing methods and special resistor designs are improving. Onics Power Resistor is still leading innovative solutions that meet the needs of modern engineering. As businesses change, HPGGRs will continue to be at the cutting edge of power control tools.